Affiliate Disclosure

Plumber Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

What Is a Non Return Valve Plumbing? Ever thought about how your plumbing stops water from flowing backward? This could lead to contamination. Non-return valves, or check valves, are key to keeping your water safe.

A non-return valve plumbing system is vital for one-way water flow. It lets water move in one direction. This stops backflow, which could bring harmful stuff into your clean water.

Knowing about non-return valves is important for keeping your water safe and working well. These devices work quietly to keep your water clean and stop contamination.

Key Takeaways

- Non-return valves prevent backward water flow

- Check valve functions protect water quality

- Essential for maintaining plumbing system integrity

- Used in residential and commercial applications

- Helps prevent possible contamination risks

Table of Contents

Understanding What Is a Non Return Valve Plumbing

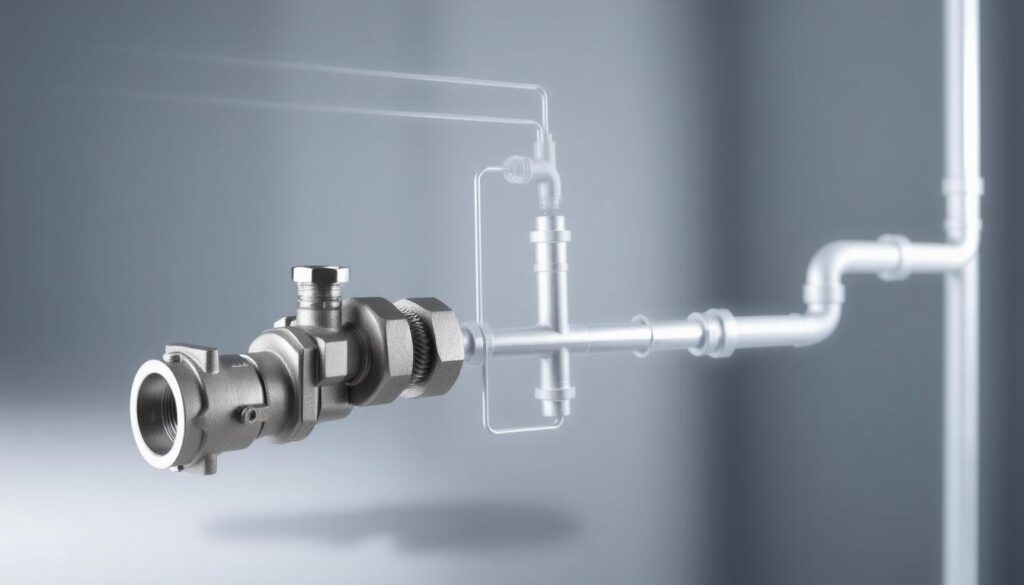

A backflow prevention device is key to keeping your plumbing safe. Non-return valves stop unwanted water flow. This helps keep your pipes clean and safe.

These valves let fluid move only one way. They are vital for many plumbing jobs.

Basic Components and Structure

A non-return valve has a few main parts:

- Valve body: The main housing that contains internal mechanisms

- Disc or check mechanism: Allows forward flow and prevents reverse flow

- Seat: The surface where the disc rests to create a seal

- Ports: Inlet and outlet connections

Working Principles of Non-Return Valves

These valves work on a simple yet smart idea. They open and close based on pressure differences. This happens without anyone needing to do it.

| Flow Condition | Valve Status | Action |

|---|---|---|

| Forward Pressure | Open | Allows fluid passage |

| Reverse Pressure | Closed | Blocks backflow |

The Role in Plumbing Systems

Non-return valves are vital in plumbing. They stop contamination, protect equipment, and keep systems running well. They make sure fluid flows the right way.

In homes and businesses, these valves are a must. They keep water clean and stop contamination in plumbing.

Types of Non-Return Valves for Plumbing Applications

Plumbing backflow prevention uses different non-return valves. These valves protect water systems from contamination and reverse flow. Knowing about these valve types helps you pick the best one for your plumbing needs.

There are several important non-return valve types. Each has its own features, making it right for certain uses. Let’s look at the most common ones:

Swing Check Valves

Swing check valves use a hinged disc to control water flow. When water moves the right way, the disc opens. But if it moves the wrong way, the disc closes, stopping backflow.

- Ideal for horizontal pipe installations

- Simple mechanical design

- Cost-effective plumbing backflow prevention

Ball Check Valves

Ball check valves have a floating ball that moves to control fluid. The ball goes up when water flows the right way and drops to block backflow.

- Excellent for vertical pipe systems

- Minimal pressure drop

- Suitable for various fluid viscosities

Spring-Loaded Check Valves

Spring-loaded check valves use a spring to close quickly and reliably. The spring adds extra force to stop backflow in tough situations.

| Valve Type | Best Application | Flow Control Efficiency |

|---|---|---|

| Swing Check | Horizontal Pipes | 70-80% |

| Ball Check | Vertical Pipes | 85-90% |

| Spring-Loaded | High-Pressure Systems | 90-95% |

“Selecting the right non-return valve is key to keeping water systems safe and clean.” – Plumbing Engineering Quarterly

Each valve type has its own benefits for preventing backflow. Choosing the right one depends on your system’s needs.

Benefits of Installing Non-Return Valves

Non-return valves are key in plumbing systems, bringing many benefits. They control water flow direction and protect your home’s plumbing. They stop reverse water movement and prevent contamination.

Knowing the role of backwater valves is important. It helps homeowners see their value in keeping systems safe. Let’s look at the main advantages:

- Prevents Backflow Contamination

- Protects Expensive Plumbing Equipment

- Enhances System Efficiency

- Ensures Compliance with Plumbing Codes

Water flow direction control is vital for health. Non-return valves act as a barrier. They stop contaminated water from flowing back into clean water sources.

| Benefit | Impact |

|---|---|

| Contamination Prevention | Blocks reverse water movement |

| Equipment Protection | Reduces mechanical stress on pipes |

| System Efficiency | Improves overall plumbing performance |

Non-return valves are your first line of defense in maintaining a safe and efficient plumbing system.

By using these valves, you protect your home from water damage and contamination. They ensure water flows smoothly and prevent backflow. This saves you from costly repairs.

Common Applications in Residential and Commercial Plumbing

Non-return valves are key in keeping plumbing systems safe. They work in homes and big commercial places. They help manage water well. Knowing how they work can help you choose the right plumbing valve installation.

- Desalination plants

- Water and waste management

- Chemical processing

- Food and beverage production

- Geothermal energy systems

- Mining operations

- Oil and gas industry

Water Supply Systems

In water systems, non-return valves stop water from flowing backward. This keeps your drinking water clean and safe. Regular check valve maintenance lowers the chance of water contamination.

Drainage and Sewage Systems

Non-return valves are key in drainage and sewage. They stop sewage from backing up during heavy rain or system overload. This protects your property from water damage and health risks.

Pump Protection Applications

Pumps are big investments in homes and businesses. Non-return valves protect these pumps from damage by stopping reverse flow. This keeps the pump working well.

| Application Area | Primary Function | Key Benefit |

|---|---|---|

| Residential Plumbing | Prevent Water Contamination | Ensure Safe Drinking Water |

| Commercial Irrigation | Control Water Flow Direction | Optimize Water Distribution |

| Industrial Processing | Protect Equipment | Reduce Maintenance Costs |

Installation Guidelines and Best Practices

Installing a one way valve needs careful attention and technical knowledge. When you start the plumbing valve installation, follow key guidelines. This ensures the system works well and is reliable.

Before starting, make sure you have these tools:

- Adjustable wrench

- Pipe thread sealant

- Measuring tape

- Appropriate safety equipment

When installing, focus on the valve’s flow direction. Most non-return valves have a directional arrow showing the right flow direction. If you install it wrong, it won’t stop backflow. This could harm your plumbing system.

“Precision in valve installation is not just about technical skill, but about protecting your entire plumbing infrastructure.” – Professional Plumbing Association

For a successful installation, consider these points:

- Check if the valve fits with your current pipe system

- Clean the pipe connections well

- Use the right pipe thread sealant

- Make sure the valve is aligned right and the pipes are not stressed

- Follow the manufacturer’s specific installation instructions

Also, remember that local building codes might have special rules for installing non-return valves. Talking to a professional plumber can help you meet these rules and get a good installation.

Maintenance and Troubleshooting Tips

Keeping your check valves in good shape is key to a reliable plumbing system. Knowing how to spot and fix problems can save you money and prevent water damage.

Regular Inspection Procedures

Regular maintenance for check valves includes several important steps:

- Inspect valve seals for signs of wear or damage

- Check for visible corrosion or mineral buildup

- Verify proper valve alignment and movement

- Listen for unusual sounds during water flow

Common Issues and Solutions

Spotting problems early can stop big failures in plumbing systems. Here are some common check valve issues:

| Issue | Potential Cause | Recommended Solution |

|---|---|---|

| Water Hammer | Rapid valve closure | Install water hammer arrestors |

| Valve Sticking | Debris or corrosion | Clean or replace valve components |

| Leakage | Worn seals | Replace valve seals |

Preventive Maintenance Steps

To keep your check valves working well, follow these steps:

- Schedule annual professional inspections

- Clean valves regularly to prevent debris accumulation

- Replace worn components promptly

- Monitor water pressure and flow characteristics

Preventive maintenance is cheaper than fixing things later. By being proactive, you can keep your plumbing systems running smoothly.

Choosing the Right Non-Return Valve

Choosing the right non-return valve is important. It’s all about matching the valve to your plumbing system’s needs. This ensures your system works efficiently.

- Pipe size and internal diameter

- Expected flow rate

- Operational pressure requirements

- Fluid or gas medium characteristics

- Environmental conditions

The material of the valve is also key. Different materials are needed for different uses. For example, stainless steel is good for water, while special alloys are better for chemicals.

When choosing a valve, think about:

- Precise pressure ratings

- Appropriate end connections

- Minimum leakage requirements

- Installation positioning

Professional tip: Always check the manufacturer’s specs to make sure the valve fits your system perfectly.

Experts say to do a full system analysis before picking a valve. Knowing your system’s needs helps get the best performance and reliability.

Safety Considerations and Regulatory Requirements

Keeping your plumbing safe means knowing about important safety rules and laws for backflow prevention devices. It’s key to understand how these devices stop harmful contamination and health risks.

Plumbing backflow prevention has many safety steps to keep water clean and safe for everyone. Laws at the local and national levels set rules for installing and keeping these devices. This ensures they work right.

- Comply with local plumbing codes

- Conduct regular device inspections

- Maintain proper installation standards

- Verify device certification

Important safety points include stopping bad water from mixing with clean water. Your backflow prevention device is a key guard. It stops contaminated water from getting back into clean water lines.

| Regulatory Aspect | Safety Requirement |

|---|---|

| Installation Standards | Meet local plumbing code specifications |

| Inspection Frequency | Annual professional assessment |

| Device Certification | Verified by authorized testing agency |

Experts say it’s smart to test and fix your backflow prevention device often. This keeps it working well and follows the latest safety rules. Being ahead of the game keeps your water safe and avoids health dangers.

Safety in plumbing is not an option—it’s a necessity.

Conclusion

Knowing what a non return valve plumbing is key for keeping your water systems safe and efficient. These devices are vital for stopping backflow and keeping your plumbing in top shape.

The check valve function is a major safety feature for both homes and businesses. The right non-return valve can keep your water clean, prevent pipe damage, and keep your system running smoothly.

Choosing the right valve, following installation rules, and doing regular checks are important. By taking care of these valves, you can avoid plumbing problems and make your water system last longer.

Learning about non-return valves can save you money and stress in the future. Make sure to get professional advice and use high-quality equipment to protect your plumbing.