Affiliate Disclosure

Plumber Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

What Element Makes Plumbing Pipes Strong? Ever thought about what makes pipes strong enough to handle high pressures and harsh conditions? It’s all about material science and the right mix of elements.

Plumbing has come a long way from lead and clay days. Now, copper pipes are the go-to for their strength and performance. To understand why, we need to explore material engineering and design.

Your home’s plumbing is a complex system. It uses materials that resist corrosion, handle temperature changes, and stay strong for years.

Key Takeaways

- Material selection directly impacts pipe strength and longevity

- Chemical composition plays a critical role in pipe performance

- Modern plumbing technologies offer superior durability compared to traditional materials

- Copper remains a top choice for plumbing pipe materials

- Innovative engineering keeps improving pipe strength and reliability

Table of Contents

Understanding Modern Plumbing Pipe Materials

Plumbing technology has changed a lot, moving from old metal pipes to new materials. These new materials work better. Your home’s pipes are a big engineering achievement that keeps getting better.

Looking at plumbing materials shows us how far we’ve come. We’ve made pipes last longer by using new chemicals. These chemicals make the pipes stronger.

Evolution of Plumbing Materials

Today’s plumbing materials use smart designs. Some big changes include:

- Switching from metal to mix materials

- Using synthetic polymers like PVC

- Creating pipes that don’t rust

Role of Chemical Composition

The chemicals in pipes affect how well they work. For example, PVC is great at not breaking down. Galvanized steel pipes use zinc to fight rust.

Modern materials are not just about strength, but about intelligent design that adapts to diverse environmental conditions.

Impact of Material Science on Pipe Strength

Scientists have made pipes better by studying their molecules. New steel and PVC pipes last a long time. They work well for homes and businesses.

Choosing the right pipes can make your place last longer and need less fixing.

The Strength of Copper in Plumbing Systems

Copper is a key player in today’s plumbing world. It shines in both homes and businesses. Its special qualities make it a top pick for many.

So, what makes copper pipes stand out? They offer many benefits. Here are a few:

- Exceptional durability

- Resistance to corrosion

- Long-lasting performance

- Natural antimicrobial properties

Copper’s strength is a big plus for your plumbing. It can handle tough conditions. Copper pipes stay strong for years, even in harsh weather.

Plumbers love copper for its dependability. It comes in different thicknesses for different needs:

- Type K: Heaviest wall thickness

- Type L: Medium wall thickness

- Type M: Thinnest standard wall thickness

Even though copper pipes cost more upfront, they save money in the long run. They need less upkeep, leak less, and keep water clean.

Copper pipes represent a time-tested solution in modern plumbing technology.

What Element Makes Plumbing Pipes Resistant to Corrosion

Keeping plumbing systems from corroding is key to lasting infrastructure. Various elements and technologies help prevent pipe damage. This keeps your water system reliable and efficient.

Galvanized steel pipes have long been used to fight corrosion. Their zinc coating acts as a strong barrier against rust and environmental harm. Brass fittings add extra protection against chemical damage.

Chemical Elements in Anti-Corrosion Protection

Some chemical elements make pipes last longer. These include:

- Zinc coating on galvanized steel pipes

- Copper alloy components

- Specialized metallic treatments

- Protective polymer layers

Importance of Zinc Coating

Zinc acts as a shield for metal pipes. When it gets wet, zinc forms a protective layer. This layer stops oxygen from reaching the steel, making the pipe last longer.

| Material | Corrosion Resistance | Typical Lifespan |

|---|---|---|

| Galvanized Steel | High | 40-50 years |

| Brass Fittings | Moderate to High | 30-40 years |

| Unprotected Steel | Low | 10-15 years |

Modern Corrosion Prevention Technologies

New technologies offer better protection. Nanotechnology coatings and smart materials are making pipes last even longer. These advancements could extend pipe life by decades.

Knowing about these technologies helps you choose the best for your plumbing. This ensures your system works well for years to come.

PVC and CPVC: Revolutionary Plastic Components

Plastic pipes have changed the plumbing world, with PVC and CPVC at the forefront. The pvc pipe composition is a big step forward. It brings durability and flexibility to homes and businesses.

Why are PVC and CPVC so loved? They offer benefits that metal pipes can’t match:

- Lightweight design

- Resistance to corrosion

- Cost-effective installation

- Long-lasting performance

PVC and CPVC differ in their makeup. Chlorinated polyvinyl chloride (CPVC) has more chlorine. This makes it better at handling heat and lasting longer.

“Plastic pipes represent the future of efficient plumbing solutions.” – Engineering Innovations Magazine

Choosing the right pipes is important. CPVC can handle hotter temperatures than PVC. This makes it perfect for hot water systems and industrial use.

| Property | PVC | CPVC |

|---|---|---|

| Temperature Resistance | Up to 140°F | Up to 200°F |

| Chemical Resistance | Good | Excellent |

| Cost | Lower | Slightly Higher |

Modern plumbing needs new ideas. PVC and CPVC pipes keep getting better. They offer top-notch performance and reliability for your projects.

Steel and Iron: Traditional Strength Elements

Plumbing has a long history of using strong materials like steel and iron. These materials, including galvanized steel pipes and cast iron drain pipes, have been key in building structures for many years. They bring special strengths to water systems and drainage.

Knowing about these materials helps us see their importance in plumbing. Steel and iron are made to last, even in tough conditions.

Metallurgical Properties of Pipe Materials

Galvanized steel pipes are strong because of their zinc coating. This coating stops rust. The making process includes:

- Zinc layer application for rust prevention

- Enhanced mechanical strength

- Resistance to environmental degradation

Heat Treatment Processes

Heat treatment makes cast iron drain pipes better. Important steps are:

- Tempering to reduce brittleness

- Normalizing for uniform grain structure

- Annealing to relieve internal stresses

Structural Integrity Considerations

Choosing between galvanized steel and cast iron pipes depends on several things. These include wall thickness, joint design, and use. New technologies are making these materials even better and longer-lasting.

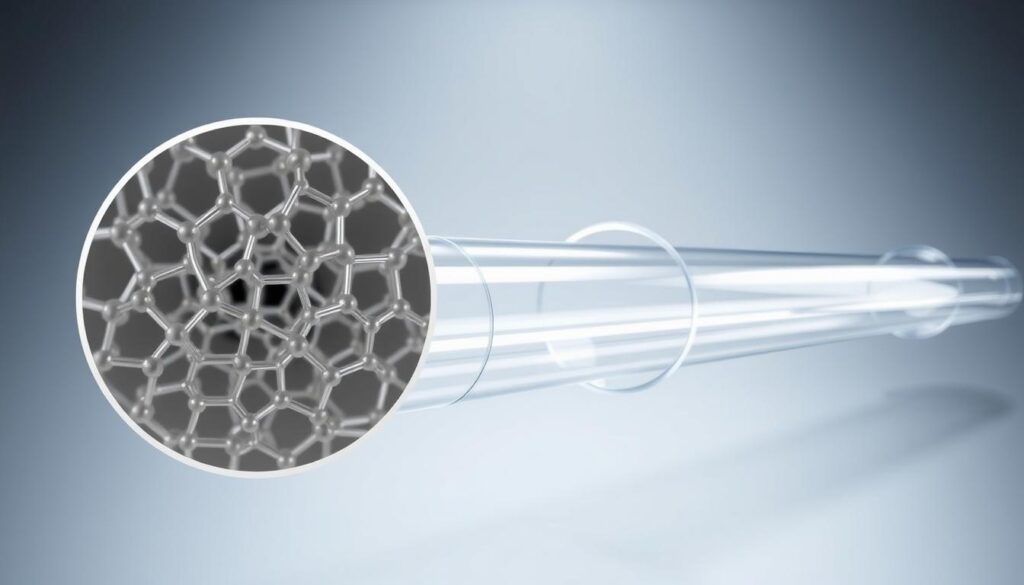

Cross-Linked Polyethylene: Advanced Molecular Structure

PEX tubing for water lines is a game-changer in plumbing. It uses advanced molecular engineering. This makes it stand out from old piping solutions.

Cross-linked polyethylene (PEX) changes regular polyethylene in a special way. It makes pipes stronger and more flexible. These pipes can handle extreme temperatures and pressures well.

- Type A PEX: Most flexible variant

- Type B PEX: Medium flexibility

- Type C PEX: Stiffest configuration

The cross-linking process is key to PEX’s durability. It links polymer chains together. This makes the material strong against:

- Temperature changes

- Chemical damage

- Physical stress

“PEX represents the future of intelligent plumbing design” – Engineering Materials Journal

| PEX Type | Flexibility | Primary Use |

|---|---|---|

| Type A | High | Residential Plumbing |

| Type B | Medium | Commercial Applications |

| Type C | Low | Repair Work |

PEX tubing beats metal pipes in many ways. It’s faster to install, has fewer connections, and lasts longer. Your plumbing system will work better with this advanced material.

The Science Behind Pipe Material Durability

To understand how long plumbing pipes last, we need to dive into material science. The key elements that make pipes strong are vital for a reliable water system in your home.

Brass fittings are key to a plumbing system’s performance. They add to the system’s strength and durability. Manufacturers pick materials based on several important factors:

- Molecular composition

- Structural resistance

- Environmental adaptability

- Chemical stability

Scientists study many elements to figure out what makes pipes last long. Copper, zinc, and certain alloys make strong materials. These materials can handle extreme conditions well.

The molecular structure of pipes is what lets them resist:

- Corrosion

- Temperature changes

- Mechanical stress

- Chemical interactions

Engineers use advanced tests to make plumbing materials even stronger. Accelerated aging tests mimic years of wear and tear. This lets researchers predict how well materials will perform over time.

The right material can mean the difference between a reliable water system and costly repairs.

When picking plumbing materials, think about your area’s environment and water. Each material has its own benefits. Getting advice from a professional is key to making the best choice.

Future Innovations in Plumbing Material Technology

The plumbing world is seeing big changes thanks to new tech. These changes are making pipes stronger, more eco-friendly, and better at what they do.

New materials are being made that are stronger and last longer. They also meet strict rules about not having lead in them.

Emerging Composite Materials

New composite materials are bringing big improvements to plumbing:

- Hybrid polymer blends with enhanced structural integrity

- Nanotechnology-enhanced pipe materials

- Self-reinforcing molecular structures

Smart Pipe Technologies

The future of plumbing includes smart systems that can:

- Detect leaks right away

- Fix small problems on their own

- Check water quality without help

| Technology | Key Benefits | Potential Impact |

|---|---|---|

| Sensor-embedded pipes | Continuous monitoring | Reduced water damage |

| Adaptive materials | Self-healing capabilities | Extended infrastructure lifespan |

| Eco-friendly composites | Sustainable production | Lower environmental footprint |

Sustainable Material Development

People are now thinking more about the planet when making plumbing materials. Sustainable solutions are key, with a focus on:

- Using recycled materials

- Making pipes that can break down naturally

- Lowering the carbon footprint of making them

These new ideas are set to change plumbing for the better. They promise systems that are stronger, use less energy, and are kinder to our planet.

Conclusion

Choosing the right plumbing pipe material is key for a water system’s success. Each material has its own strengths, from metals to modern plastics like PEX tubing. Knowing what makes pipes strong helps you choose wisely for your home.

Many factors influence your piping choice, like water chemistry and pressure. Copper is durable, while PEX is flexible and resistant to corrosion. Steel and iron are strong, but new composite materials are changing plumbing.

Recent advancements in pipe materials are exciting. PEX tubing, for example, is a big step forward. It’s lightweight and doesn’t corrode, unlike older materials. Think about durability, cost, and upkeep when picking pipes.

The ideal plumbing solution is strong, affordable, and eco-friendly. Talking to professional plumbers can guide you through the many options. They can help you find the best fit for your needs.