Affiliate Disclosure

Plumber Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

What Does MIP Mean in Plumbing? Ever wondered what MIP means in plumbing systems? Knowing this can save you time, money, and avoid installation problems.

MIP fittings are key in modern piping systems. They connect Male Iron Pipe, making plumbing networks secure and reliable. This is true for homes, businesses, and factories.

Plumbing might seem hard, but learning about MIP makes it easier. It’s important for DIY fans and pros alike to know about MIP fittings.

Key Takeaways

- MIP stands for Male Iron Pipe with external threading

- Used in various plumbing connection scenarios

- Essential for creating secure pipe connections

- Applicable in residential, commercial, and industrial environments

- Understanding MIP helps improve plumbing project outcomes

Table of Contents

Understanding Basic Plumbing Terminology

Plumbing has its own language. Knowing the terms can save you time and avoid mistakes. It’s useful for both DIY fans and pros.

For beginners, plumbing abbreviations might seem hard to grasp. Let’s cover some key terms. They’ll help you talk plumbing better and understand your system.

Common Plumbing Thread Types

Thread types are key for pipe connections. Here are the main ones you’ll see:

- NPT (National Pipe Thread): The standard in North America

- MIP (Male Iron Pipe): Has external threads

- FIP (Female Iron Pipe): Has internal threads for male connections

The Role of Pipe Fittings in Plumbing Systems

Pipe fittings are plumbing’s hidden stars. They link pipes, change direction, and control water flow.

| Fitting Type | Primary Function | Common Applications |

|---|---|---|

| Elbow | Changes pipe direction | Works around obstacles |

| Coupling | Joins two pipes | Extends pipe runs |

| Reducer | Links pipes of different sizes | Adjusts pipe sizes |

Essential Plumbing Components Overview

Knowing plumbing terms helps you talk plumbing and fix problems fast. Key parts include valves, joints, and connections. They keep your plumbing system working well.

“Knowledge of plumbing terminology is the first step to becoming a confident DIY plumber.” – Professional Plumbing Association

What Does MIP Mean in Plumbing?

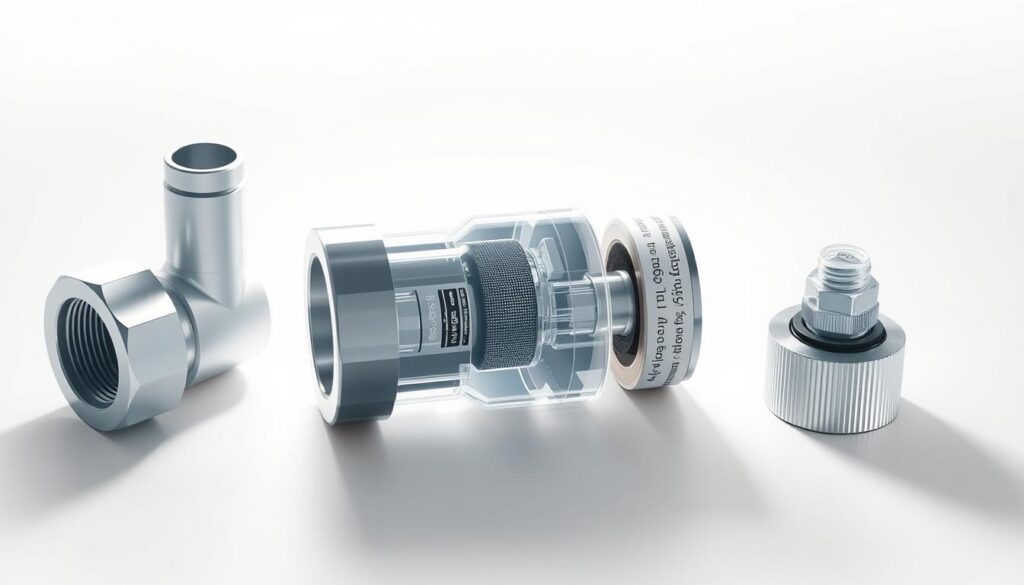

Understanding male iron pipe (MIP) in plumbing is key for anyone working with pipes. MIP fittings are special parts made for strong and reliable connections in many piping systems.

The term MIP means pipe fittings with threads on the outside. These threads let them screw into female connections. Male iron pipe fittings are essential for making tight, leak-free seals in plumbing.

- External threading allows direct connection to female fittings

- Commonly manufactured from materials like brass, steel, and PVC

- Provides a robust and reliable pipe connection method

When picking MIP plumbing fittings, look at a few important things:

| Material | Durability | Common Applications |

|---|---|---|

| Brass | High corrosion resistance | Residential water lines |

| Steel | Exceptional strength | Industrial piping systems |

| PVC | Chemical resistance | Irrigation and drainage |

Both pros and DIY folks use MIP fittings for their flexibility and simple setup. The outside threads make quick connections. They also keep a tight seal to stop leaks and keep plumbing systems working well.

MIP vs. FIP: Key Differences Explained

It’s important to know the difference between MIP and FIP connections for plumbing projects. These fittings may look alike, but they work differently. This affects how well they perform and where they can be used.

MIP connections have threads on the outside. They screw into female fittings. The main difference is where the threads are and how they face.

Physical Characteristics Comparison

- MIP (Male Iron Pipe) fittings have external threads

- FIP (Female Iron Pipe) fittings have internal threads

- Thread size and pitch determine compatibility

Application Scenarios

Choosing between MIP and FIP depends on your plumbing needs. Homes and businesses need different connections. This is because of the type of pipe and the system’s design.

- Water supply lines

- Drainage systems

- Industrial piping networks

Installation Requirements

Installing MIP connections needs careful attention. You must seal the threads and align them right. Use thread sealant and tighten carefully to avoid leaks.

Tools like pipe wrenches, thread tape, and pipe dope help. They ensure connections between MIP and FIP fittings are secure and leak-free.

MIP Thread Design and Specifications

Understanding MIP thread design is key for plumbing pros. Male Iron Pipe (MIP) threads are a basic part of plumbing. They have special features for strong connections.

MIP fittings have a thread design that meets high standards. These threads have important features for the best performance. They include:

- Straight thread pattern with precise pitch

- Standard National Pipe Thread (NPT) configuration

- Specific thread angle for secure sealing

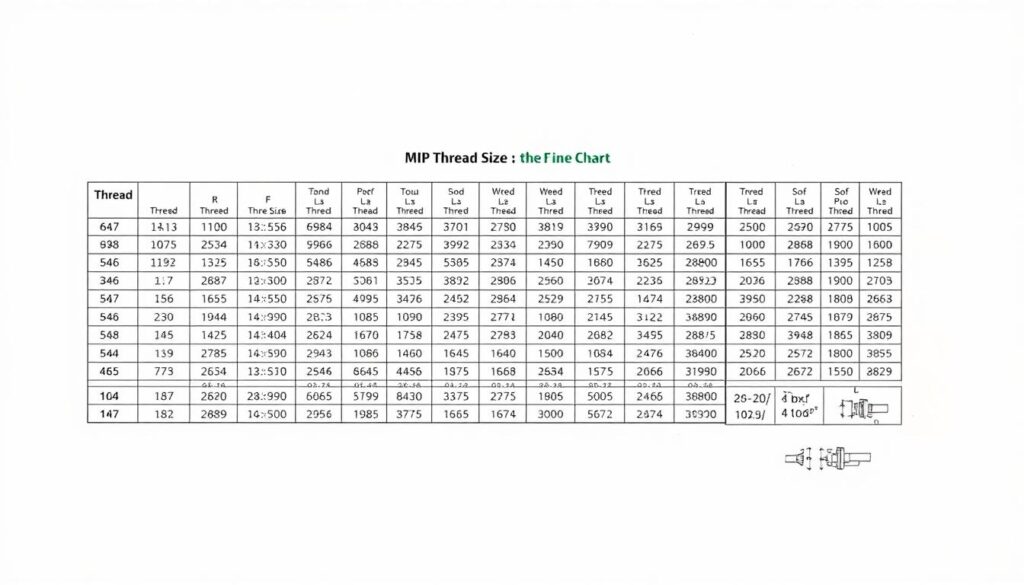

A mip thread size chart shows many sizes, from 1/8 inch to 4 inches. Each size is made for different plumbing needs. This ensures they work well together.

Important parts of MIP thread design are:

- Precision thread cutting

- Consistent thread depth

- Smooth internal surface

For MIP threads, sealing is done with Teflon tape or pipe dope. These help make a tight seal. Plumbers use these details to avoid leaks and keep systems working right.

Proper thread design is the foundation of reliable plumbing connections.

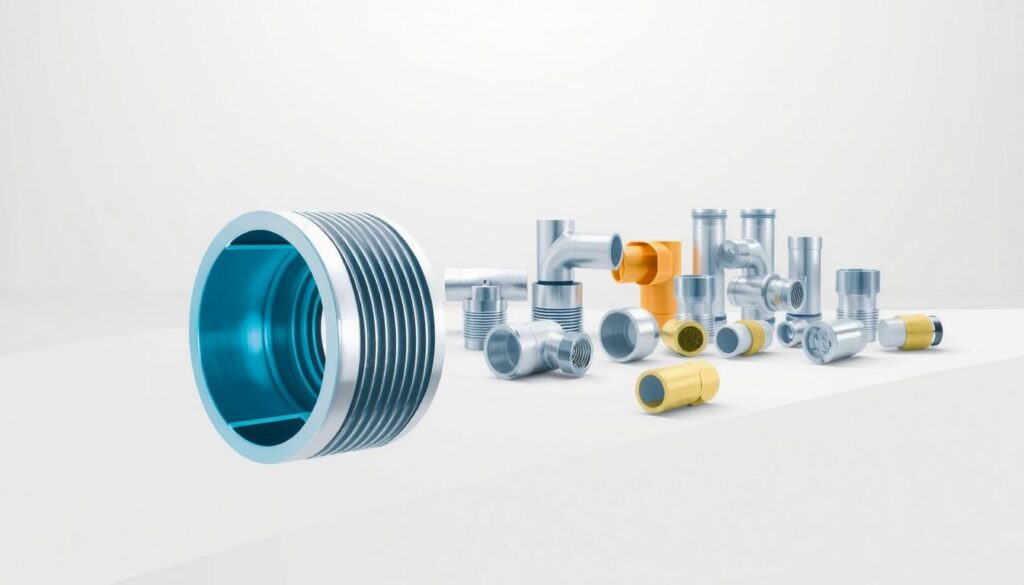

Common Applications of MIP Fittings

Male iron pipe (MIP) fittings are key in many plumbing systems. They are used in homes, businesses, and factories. Knowing how to use MIP fittings helps you pick the right one for your plumbing needs.

Plumbing experts love MIP fittings for their strength and ability to connect well. Let’s look at where they are mostly used:

Residential Plumbing Uses

In homes, MIP fittings are very important:

- They connect water heater pipes

- They help install faucets

- They link shutoff valves

- They fix water lines

Commercial Applications

Big buildings need strong plumbing. MIP adapters are great for:

- Big water systems

- Connecting HVAC

- Setting up irrigation

- Water systems in cities

Industrial Setting Applications

Factories need top-notch pipes. MIP fittings are vital for:

- Connecting high-pressure pipes

- Chemical equipment

- Cooling systems in factories

- Hydraulic systems

“The versatility of MIP fittings makes them an indispensable component in modern plumbing infrastructure.” – Plumbing Engineering Journal

Whether it’s a home fix or a big industrial job, knowing about MIP fittings helps. It lets you choose the best fitting for your project.

Understanding MIP Thread Sizes and Standards

Exploring plumbing pipe fitting terms can be tough, like figuring out MIP thread sizes. These male iron pipe (MIP) threads are key for making strong and safe plumbing connections in many places.

When you work with MIP fittings, you’ll see many standard thread sizes. These sizes are vital for setting up your plumbing project right. The mip thread size chart helps you pick the right parts for your job.

- Standard thread sizes range from 1/8″ to 2″ for most homes

- Big sizes up to 6″ or more are needed for industrial places

- Threads follow National Pipe Thread (NPT) standards

The American National Standards Institute (ANSI) and ASME give rules for thread sizes and how tight they should be. These rules make sure different makers’ parts work together well. They also help keep plumbing systems reliable.

| Nominal Pipe Size | Thread Size | Typical Application |

|---|---|---|

| 1/4″ | NPT 1/8″ | Small appliance connections |

| 1/2″ | NPT 1/2″ | Residential water lines |

| 1″ | NPT 1″ | Commercial plumbing |

Knowing these thread sizes and rules is key for picking the right parts. It ensures your plumbing project has a tight, leak-free connection.

Installation Guide for MIP Fittings

Installing MIP fittings needs precision and the right steps. Knowing how to spot MIP connections is key for a secure plumbing system. Both pros and DIY folks can do a great job with these tips.

Essential Tools and Materials

First, get these important tools ready:

- Adjustable wrench

- Thread sealant (Teflon tape or pipe dope)

- Clean cloth or wire brush

- Protective gloves

- Pipe cutter or hacksaw

Step-by-Step Installation Process

Follow these steps for MIP plumbing fittings:

- Clean pipe and fitting threads well

- Check threads for damage or rust

- Put on thread sealant evenly

- Line up fittings carefully

- Hand-tighten first

- Use wrench for final tightening

Avoiding Common Installation Mistakes

Watch out for these common mistakes:

- Over-tightening which can harm threads

- Not enough thread sealant

- Connecting pipes wrong

- Not checking threads

- Using the wrong materials

Right installation means your plumbing works well and doesn’t leak. Always be careful and precise with MIP fittings.

MIP Connection Methods and Best Practices

Working with male iron pipe (MIP) fittings is key in plumbing. Knowing how to connect them right is vital for a leak-free system. Both pros and DIY folks need to focus on the right techniques for strong connections.

Choosing the right connection method is important. It depends on careful preparation and precise steps. Your success in plumbing projects depends on it.

- Inspect threads for damage or debris before connection

- Clean threading surfaces thoroughly

- Choose appropriate thread sealant

- Ensure proper alignment of pipe and fitting

Thread sealants are key for watertight seals. You have two main options:

| Sealant Type | Pros | Cons |

|---|---|---|

| Teflon Tape | Easy application, clean process | Less effective for high-pressure systems |

| Pipe Dope | Superior sealing, versatile | Messier application, possible chemical issues |

“Proper preparation prevents poor performance in plumbing connections.” – Professional Plumber’s Wisdom

For the best MIP connections, use thread sealant wisely. Wrap Teflon tape clockwise around male threads, ensuring smooth and even coverage. Don’t over-tighten, as it can harm threads and ruin the seal.

Troubleshooting MIP Fitting Issues

Knowing how to spot MIP connections and fix common plumbing problems is key. MIP plumbing fittings can face issues that need careful checking and fixing.

When you’re fixing MIP connections, pay attention to a few important things:

- Leak detection around threaded connections

- Thread integrity and possible damage

- Right sealing methods

- Material matching

Common MIP fitting problems usually come from wrong installation or bad thread sealing. Look for signs like:

- Visible water seepage around connection points

- Irregular threading or cross-threading

- Corrosion or material wear signs

To fix MIP fitting issues, follow these steps:

- Check threads for full and clean fit

- Use the right thread tape or pipe sealant

- Tighten properly without overdoing it

- Make sure materials match

Professional tip: Always use the correct tools and follow manufacturer guidelines when working with MIP plumbing fittings.

By knowing these fixing methods, you can stop leaks and make your plumbing last longer.

Safety Considerations When Working with MIP Fittings

Working with MIP adapter uses in plumbing systems requires safety. Knowing how to handle these fittings can avoid hazards and make your plumbing last longer.

Both plumbing pros and DIY fans need to focus on important safety points with MIP (Male Iron Pipe) fittings.

Pressure Ratings and Limitations

Knowing the pressure ratings is key for safe plumbing. Each MIP fitting has a specific pressure limit that must not be crossed. Here are some important points:

- Always check the manufacturer’s max pressure ratings

- Make sure the material is strong enough

- Think about how the environment might affect pressure

Material Compatibility Guidelines

Choosing the right materials is vital in plumbing. Using the wrong ones can cause corrosion, leaks, and system failures.

| Material Type | Compatibility Rating | Recommended Use |

|---|---|---|

| Brass | Excellent | Potable water systems |

| Galvanized Steel | Good | Industrial applications |

| PVC | Limited | Non-pressure systems |

Maintenance Requirements

Regular upkeep is essential to avoid safety risks. Regular checks and timely replacements keep your plumbing system safe.

- Inspect fittings every three months for wear

- Look for leaks or corrosion

- Replace weak fittings right away

Safety in plumbing is not an option—it’s a necessity.

Conclusion

Knowing what MIP means in plumbing is key for good piping jobs. MIP (Male Iron Pipe) threads are a basic way to connect pipes in homes, businesses, and factories. Learning about these fittings can make your plumbing systems work better.

When you look at MIP vs NPT plumbing, it’s clear that the right thread and how you install it matter a lot. Choosing the right fitting, knowing the pressure limits, and making sure materials match are all important. Both pros and DIY folks can get better at plumbing by learning these important connection skills.

Keeping safe is always the top priority with MIP fittings. Make sure to install them correctly, use the right tools, and check the thread specs before you connect pipes. By following the tips in this guide, you can make plumbing systems that are reliable and meet high standards, reducing the chance of problems.

Staying committed to learning and using precise plumbing methods will make your pipe installations stronger and more effective. Always keep learning and pay close attention to the details in your plumbing work.