Affiliate Disclosure

Plumber Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

Ever wondered why your DIY plumbing project went wrong? The secret might be in knowing how to measure plumbing fitting size accurately.

Getting the plumbing pipe diameter right is key to any plumbing job. Whether you’re a homeowner or a pro plumber, knowing how to measure can save you a lot. It saves time, money, and avoids frustration.

Measuring plumbing might seem hard, but with the right info, you can pick the right fittings. If you get it wrong, you might face leaks, bad connections, and expensive fixes.

Key Takeaways

- Precise measurements are critical for successful plumbing projects

- Understanding diameter and fitting types prevents installation errors

- Different materials require specific measurement techniques

- Professional tools can improve measurement accuracy

- Knowing measurement standards helps prevent costly mistakes

Table of Contents

Understanding Basic Plumbing Measurement Terminology

Plumbing measurements can be tricky for both pros and DIY fans. Knowing the key terms is key for finding the right fit.

Plumbing measurements cover important concepts. These concepts are vital for your project’s success. Let’s explore the essential terms you need to know.

Outside Diameter (OD) vs Inside Diameter (ID)

Understanding the difference between outside and inside diameter is key:

- Outside Diameter (OD): This is the pipe’s outer width

- Inside Diameter (ID): This is the inner space where fluid moves

Nominal Size vs Actual Dimensions

Pipe sizing can be confusing. The nominal size doesn’t always match the real measurements. For instance, a 1-inch pipe might not be exactly 1 inch wide.

| Nominal Size | Actual OD | Actual ID |

|---|---|---|

| 1/2 inch | 0.840 inches | 0.622 inches |

| 3/4 inch | 1.050 inches | 0.810 inches |

| 1 inch | 1.315 inches | 1.049 inches |

Wall Schedule and Thickness

Wall schedule shows the pipe’s thickness. This affects its strength and inner diameter. Different schedules mean different performance levels.

Pro tip: Always check both nominal size and actual measurements when picking plumbing fittings.

Essential Tools for Measuring Plumbing Fittings

Getting accurate plumbing measurements is key. You need the right tools for this. Knowing how to use these tools is very important. It helps when you’re using a plumbing connector size chart or a water pipe size calculator.

Professional plumbers use several important tools for accurate measurements:

- Digital Calipers: Gives you precise outside and inside diameter measurements

- Tape Measures: Helps find the length of pipes and fittings

- Pipe Gauges: Quick way to check pipe diameters

- Thread Pitch Gauges: Accurately finds thread specifications

Digital tools have big advantages over old methods. Digital calipers can quickly change units and give you measurements. This is very helpful when you’re using a water pipe size calculator.

Pro tip: Always calibrate your digital measurement tools before starting any plumbing project. This ensures the highest accuracy.

Buying good measurement tools saves time and avoids expensive errors. With a detailed plumbing connector size chart and precise tools, you can face any plumbing challenge confidently.

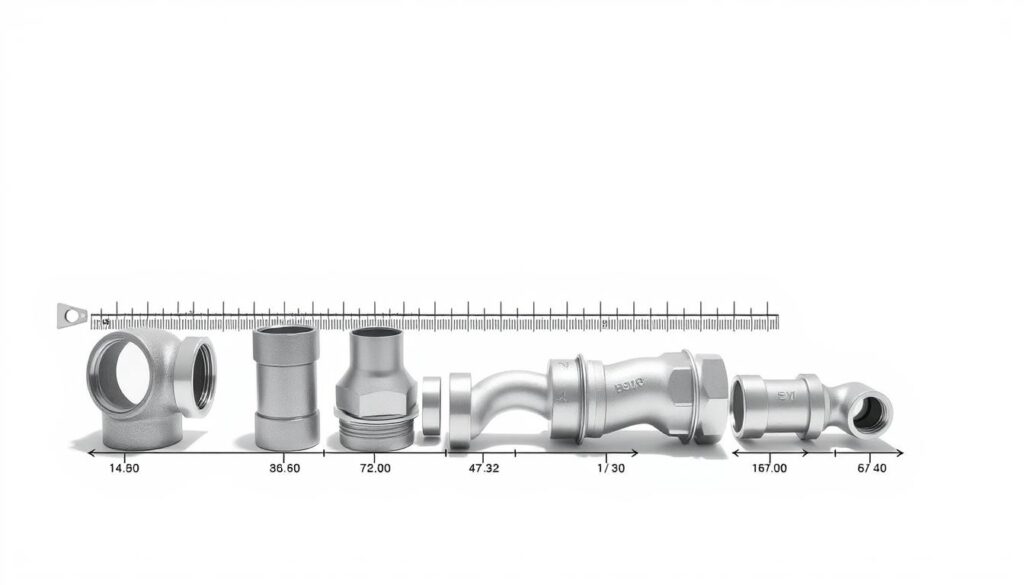

Common Types of Plumbing Fittings and Their Sizing

Understanding plumbing fittings is key for any plumbing project. Knowing how to measure and choose the right fittings is vital. Your skills in copper fitting measurement and PVC pipe size determination are essential.

Plumbing fittings come in many shapes and sizes. Each is made for a specific purpose. Learning to measure and pick the right fitting can save you time and money.

Adapters and Bushings: Connecting Different Pipes

Adapters are vital in plumbing systems. They connect pipes of different sizes or materials. With a copper fitting measurement guide, adapters help link:

- Different pipe diameters

- Dissimilar pipe materials

- Varying thread types

Couplings and Unions: Seamless Pipe Connections

Couplings and unions are key for joining straight pipe sections. They might look similar, but they serve different purposes. Couplings are permanent, while unions are for easy disconnection during maintenance.

Elbows and Tees: Directing Pipe Flow

Elbows and tees are important for changing pipe direction. Elbows make angular connections, usually at 45 or 90 degrees. Tees allow for branch connections in three directions.

Be careful when choosing fittings. Make sure they fit well and match your plumbing system.

How to Measure Plumbing Fitting Size

Getting the right size for plumbing fittings is key for any project. Whether you’re tackling it yourself or you’re a pro, knowing how to measure is essential. It’s all about precision and the right methods.

For male pipe threads, measure the outside diameter at the widest part. Use a caliper or tape to get the full width of the thread’s edge. Experts say to take several measurements to be sure when measuring pipe threads accurately.

- Use a digital caliper for precise measurements

- Measure at the widest point of the thread

- Take multiple measurements to confirm accuracy

- Compare measurements with standard sizing charts

Female pipe threads need a different method. You must measure the inside diameter at the widest point. This might need special tools.

| Thread Type | Measurement Location | Recommended Tool |

|---|---|---|

| Male Threads | Outside Diameter | Digital Caliper |

| Female Threads | Inside Diameter | Thread Gauge |

Pro tip: Always check your measurements against standard pipe thread sizing charts. Even a small mistake can cause fitting issues and leaks.

Understanding Thread Types and Measurements

Threaded connections are key in plumbing. Knowing how to identify npt thread sizes is vital for good installations. Pipe threads help make connections between plumbing parts secure and leak-free.

To measure pipe threads right, you need to know a lot and have the right tools. There are many thread types, each with its own special features. These features affect how well a fitting works and if it fits at all.

Male Thread Measurements

Measuring male threads involves looking at a few important things:

- External thread diameter

- Thread length

- Number of threads per inch

- Thread direction (right or left-hand)

Female Thread Measurements

Measuring female threads is a bit different:

- Internal thread diameter

- Thread depth

- Matching thread count

- Compatibility with male thread specifications

Thread Pitch and Count

Knowing about thread pitch is key for identifying npt thread sizes. The pitch is the space between thread crests. It changes based on the pipe size and use.

| Pipe Size | Threads per Inch | Thread Pitch |

|---|---|---|

| 1/8″ | 27 | 0.0374 inches |

| 1/4″ | 18 | 0.0556 inches |

| 1/2″ | 14 | 0.0714 inches |

| 3/4″ | 14 | 0.0714 inches |

Experts say to use a thread gauge or pitch micrometer for exact measurements. This is important when working with different pipe thread types.

Material-Specific Sizing Guidelines

Knowing the exact sizing needs for different plumbing materials is key. Each material has its own special traits that affect fitting size and how well they work together.

When you’re using a copper fitting measurement guide, there are a few important things to keep in mind:

- Copper pipes usually have standard sizes

- The thickness of the walls changes with Type K, L, and M copper pipes

- Soldered joints add a little extra thickness to the connections

For PVC pipe size determination, it’s vital to understand Schedule ratings. There are two main PVC schedules:

| Schedule Type | Wall Thickness | Typical Color | Common Application |

|---|---|---|---|

| Schedule 40 | Thinner walls | White | Residential plumbing |

| Schedule 80 | Thicker walls | Gray | Industrial applications |

Your measurement method will change based on the material. Always check the pipe size before buying fittings. This ensures accurate connections and avoids leaks or system failures.

Common Fitting Materials and Their Size Standards

Choosing the right plumbing fitting material is key for a successful installation. Knowing the standard sizes helps pick the best parts for your project. Each material has its own benefits and affects the pipe’s size and system performance.

Both pros and DIYers need to think about many things when picking materials. Each option has its own strengths and weaknesses for piping systems.

PVC and CPVC Measurements

Plastic pipes like PVC and CPVC are light and don’t rust. They follow strict size rules:

- Schedule 40 and Schedule 80 setups

- Size range from 1/2 inch to 6 inches

- Colors help identify them easily

Copper Fitting Dimensions

Copper is a favorite for plumbing. It’s different because it’s soldered, not threaded. Here are its standard sizes:

| Copper Type | Typical Sizes | Common Applications |

|---|---|---|

| Type L | 1/2″ to 4″ | Residential water lines |

| Type M | 1/2″ to 2″ | Light commercial projects |

| Type K | 3/4″ to 4″ | Underground water services |

Brass and Steel Fitting Sizes

Brass and steel are strong for high-pressure and industrial needs. Their sizes are:

- Threaded connections with precise sizes

- Different thicknesses for various pressures

- Match standard pipe sizes

The right material depends on your plumbing needs, the environment, and your budget.

Avoiding Common Sizing Mistakes

Choosing the right plumbing fitting can be hard. Many DIY fans and pros make big mistakes when measuring pipe sizes. Knowing these common errors can save you time, money, and avoid installation disasters.

When dealing with plumbing connections, being precise is essential. A plumbing connector size chart is your best ally in avoiding measurement mistakes. Here are the most common sizing errors to watch out for:

- Confusing nominal size with actual pipe dimensions

- Overlooking material thickness variations

- Misinterpreting thread types and measurements

- Failing to account for different fitting materials

Your water pipe size calculator is a great tool for double-checking measurements. Pros suggest taking multiple measurements and checking them against reliable size charts.

| Common Mistake | Potential Consequence | Prevention Strategy |

|---|---|---|

| Incorrect Pipe Measurement | Leaks and Connection Failures | Use Precise Measuring Tools |

| Ignoring Material Differences | Incompatible Fitting Connections | Verify Material Specifications |

| Thread Type Mismatches | Poor Seal and Possible Breakage | Check Thread Pitch and Type |

Pro tip: Always measure twice and buy once. A few extra minutes of careful measurement can prevent costly mistakes and avoid water damage.

Remember, each plumbing project is different. Take the time to understand your specific needs and use accurate tools. This will help you get professional-quality results.

Converting Between Different Measurement Systems

Working with different measurement systems in plumbing can be challenging. It’s important to know how to switch between metric and imperial units. This knowledge is key for doing plumbing jobs right.

When you’re dealing with plumbing fittings, you often need to switch between millimeters and inches. Here are some tips to help you make these conversions smoothly:

- 1 inch = 25.4 millimeters

- 1 millimeter = 0.0394 inches

Here are some practical tips for plumbing pros:

- Always use a reliable conversion calculator

- Double-check measurements before cutting pipes

- Verify conversion charts from reputable sources

“Precision in measurement prevents costly mistakes in plumbing installations.” – Professional Plumbing Association

For accurate conversions, follow these steps:

- Identify the original measurement system

- Use standard conversion formulas

- Confirm measurements with precise tools

Remember, when working with different pipe schedules and materials, sizes can vary. PVC and copper, for example, have their own sizing rules. You need to pay extra attention when converting these.

Pro Tip: Keep a conversion reference chart in your toolbox for quick and accurate measurements.

Conclusion

Learning to measure plumbing fitting size is key to saving time and money. It also helps avoid frustration in home projects. Getting good at measuring plumbing pipe sizes takes patience and practice. But, the benefits are worth it.

By learning how to size and choose fittings correctly, you’ll avoid costly mistakes. This ensures your plumbing connections are reliable. Professional plumbers say it’s smart to take your time with precise measurements before buying parts.

It doesn’t matter if you’re working with brass, copper, or PVC pipes. The rules are the same. Use reliable sizing charts and the right tools to pick the perfect fittings every time.

Success in plumbing projects comes from paying attention to details. Always double-check your measurements. Know about thread types and the needs of your installation. If unsure, get help from experts to avoid problems like leaks or misalignments.

Knowledge is your most valuable tool. Keep learning and practicing your measurement skills. Stay up-to-date with industry standards. With effort and precision, you’ll confidently choose the right plumbing fittings for any job.