Affiliate Disclosure

Plumber Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

Which Plumbing Device Helps Prevent a Backflow ServSafe? Did you know a single backflow incident can risk your entire kitchen’s water system? Knowing which plumbing device prevents backflow ServSafe is key for food safety and public health.

Backflow prevention devices are the heroes of food service sanitation. They keep your water safe from contamination by ensuring it flows the right way. In commercial kitchens, picking the right device is vital for a safe dining experience.

Your restaurant’s water system is at risk every day. Backflow prevention devices protect against cross-contamination, keeping your water safe. Knowing about these devices is more than a rule—it’s essential for managing your kitchen responsibly.

Key Takeaways

- Backflow prevention devices are essential for maintaining water safety in commercial kitchens

- Proper device selection can prevent serious health risks

- ServSafe standards require specific backflow prevention measures

- Different types of backflow prevention exist for various kitchen scenarios

- Regular inspection and maintenance are key for effective protection

Table of Contents

Understanding Backflow and Cross-Connections in Food Service

In commercial food prep, keeping water safe is key. It’s important to know how to stop cross-connections and prevent water contamination. This keeps your kitchen safe from health risks.

Controlling cross-connections is not just a rule. It’s a safety must. Cross-connections happen when clean water meets possible contamination sources. This can lead to serious foodborne illnesses.

What Causes Backflow in Commercial Kitchens

Backflow comes from two main reasons:

- Back-pressure: When the pressure downstream is higher than the water supply pressure

- Back-siphonage: Negative pressure pulls water back through plumbing systems

Types of Cross-Connections

Food service places face different cross-connection situations:

- Direct connections between clean water and contaminated sources

- Bad connections with equipment drainage systems

- Unsafe ways of storing water

Health Risks Associated with Backflow

“Water contamination prevention isn’t optional—it’s essential for protecting public health.” – Food Safety Expert

Uncontrolled cross-connections can lead to health problems. These include bacterial infections and chemical contamination. It’s vital to have strong plans to prevent water contamination.

Knowing these risks helps food service workers take strong steps. They can protect staff and customers from harm.

The Critical Role of Potable Water in Food Safety

Potable water is key for any food service. It’s about keeping water clean and safe. Every bit of water in your kitchen affects your customers’ health.

In commercial kitchens, potable water is vital for:

- Food preparation and cooking

- Cleaning and sanitizing surfaces

- Handwashing and personal hygiene

- Dishwashing and equipment maintenance

ServSafe backflow prevention methods are essential. Bad water can make a clean kitchen unsafe. It can lead to harmful bacteria and foodborne illnesses.

| Water Usage Category | Potential Contamination Risks | Prevention Strategy |

|---|---|---|

| Food Preparation | Bacterial growth | Regular water quality testing |

| Equipment Cleaning | Chemical cross-contamination | Backflow prevention devices |

| Personal Hygiene | Pathogen transmission | Proper plumbing maintenance |

Your kitchen’s water system must follow strict rules. Keeping your water safe is not just a suggestion—it’s a must for food safety. With good backflow prevention, you protect your customers and your restaurant’s good name.

Which Plumbing Device Helps Prevent a Backflow ServSafe

Keeping your food service safe from water contamination is key. You need to know the best ways to prevent backflow. There are several devices that can protect your water supply from harmful cross-connections.

Experts in food safety point out a few important devices for preventing backflow. Choosing the right method is vital for keeping your kitchen’s water safe.

Air Gaps: The Primary Prevention Strategy

The top choice for preventing backflow is the air gap. It’s simple yet very effective. It creates a gap between water lines and possible contamination sources.

- Provides complete physical separation

- Eliminates direct connection risks

- Recommended by health departments nationwide

Vacuum Breakers: Additional Protection

Vacuum breakers are a strong second line of defense. They stop water from flowing backward into clean systems by breaking negative pressure.

Double Check Valve Assemblies

For complex systems, double check valve assemblies are a solid choice. They have two valves that ensure water flows only one way.

Protecting your water supply isn’t just a recommendation—it’s a critical safety requirement for any food service operation.

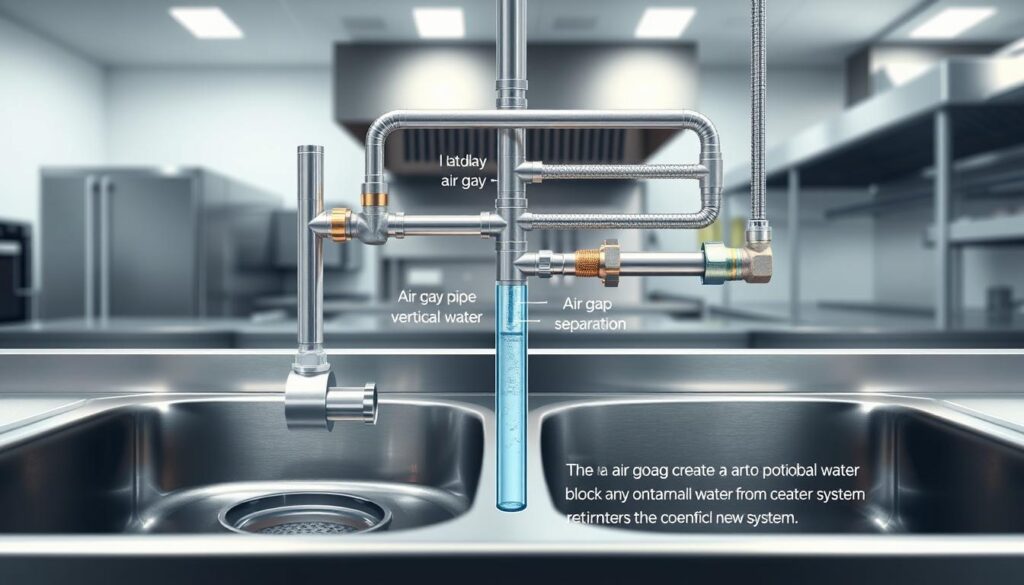

Air Gap: The Most Effective Backflow Prevention Method

In commercial kitchens, keeping your water supply safe is key for food safety. An air gap plumbing servsafe method is the top choice for preventing backflow. It makes a clear gap between your water and possible contamination sources.

An air gap creates a vertical space between the water outlet and the highest flood level of a sink or appliance. The important details are:

- Distance must be twice the diameter of the supply pipe

- Minimum separation of one inch

- Prevents direct cross-connection between clean and potentially contaminated water

When set up right, air gaps offer strong protection against backflow in kitchens. They work well in:

- Kitchen sinks

- Dishwashing stations

- Beverage preparation areas

- Ice machine connections

Food service places count on air gaps as a key safety measure. The physical space stops any backward flow of contaminated water. This keeps your kitchen clean and safe.

Proper installation and regular checks of air gaps are vital for food safety rules.

Understanding Pressure Vacuum Breakers (PVB) in Food Establishments

Keeping your food establishment’s water safe is key. Pressure vacuum breakers (PVBs) are vital for this. They help stop water contamination in commercial kitchens. These devices are essential for servsafe backflow prevention, keeping your drinking water safe.

Vacuum breakers act as a first line of defense against water risks. They block contaminated water from entering the clean water system. This is a critical step in protecting your water supply.

Installation Requirements for PVBs

Installing pressure vacuum breakers needs careful attention to several factors:

- Must be installed at least 12 inches above the highest water outlet

- Require protection from freezing temperatures

- Need direct vertical installation

- Must have an unobstructed air inlet

Maintenance and Testing Procedures

Maintaining your PVB involves regular checks and specific tests:

- Do annual professional inspections

- Look for visible damage or corrosion

- Test the check valve’s functionality

- Make sure the air inlet works right

Regular maintenance keeps your vacuum breakers working well. They protect your food establishment’s water supply.

Essential Components of Commercial Kitchen Plumbing Safety

Keeping your kitchen’s plumbing safe is key. Your water system must be checked often to avoid health risks. Using the right backflow prevention methods keeps your customers safe and follows health rules.

Important plumbing parts need special safety steps. This ensures clean water and stops contamination. These key parts are:

- Faucet backflow prevention devices

- Ice machine water supply protection

- Beverage dispenser connection safeguards

- Sink and preparation area water line barriers

Your kitchen’s plumbing needs many safety layers. Air gaps and special valves stop dirty water from getting into clean water. This is a big safety step.

| Plumbing Component | Recommended Prevention Method |

|---|---|

| Beverage Machines | Vacuum Breaker Installation |

| Ice Machines | Air Gap Protection |

| Prep Sink Faucets | Double Check Valve Assembly |

It’s vital to check and fix these safety parts often. Work with certified plumbers who know kitchen needs. This ensures your kitchen stays safe from water contamination.

Regulatory Requirements for Backflow Prevention in Restaurants

Understanding food safety plumbing rules is key. Restaurants must follow strict guidelines to keep customers safe. This ensures they meet local health department standards.

Food places have to follow strict backflow prevention rules. Knowing these rules is vital for a safe dining space.

ServSafe Compliance Standards

ServSafe sets high standards for backflow prevention. Restaurants must adhere to these rules. They include:

- Regular inspection of plumbing systems

- Documented maintenance of backflow prevention devices

- Annual certification of plumbing safety measures

Health Department Guidelines

Local health departments have specific rules to stop water contamination. Your restaurant needs to keep detailed records of plumbing safety steps.

| Requirement | Frequency | Documentation Needed |

|---|---|---|

| Backflow Device Inspection | Annually | Certified Inspection Report |

| Maintenance Records | Ongoing | Repair and Service Logs |

| Device Certification | Every 3 Years | Professional Certification |

The person in charge must document all backflow prevention steps. Keeping detailed records helps avoid health code issues. It shows your dedication to food safety.

Maintenance and Inspection of Backflow Prevention Devices

Keeping backflow prevention devices in good shape is key for food safety in commercial kitchens. Your ServsafE strategy for plumbing backflow prevention relies on regular checks and care for these systems.

Regular upkeep ensures your backflow prevention device keeps food safe by stopping contamination. It spots issues early, before they get worse.

- Inspect devices quarterly

- Test functionality annually

- Keep detailed maintenance records

- Train staff on basic device recognition

Important steps for maintaining your backflow prevention device include:

- Visual inspection for visible damage

- Checking for proper alignment

- Verifying seal integrity

- Cleaning external components

| Maintenance Activity | Frequency | Responsible Party |

|---|---|---|

| Visual Inspection | Quarterly | Certified Plumber |

| Comprehensive Testing | Annually | Backflow Specialist |

| Record Documentation | After Each Inspection | Kitchen Management |

Remember: A well-maintained backflow prevention device is your first line of defense against water contamination in food service environments.

Professional tip: Always work with certified plumbing professionals who understand food safety regulations and backflow prevention requirements.

Common Backflow Scenarios in Commercial Kitchens

Commercial kitchens face many challenges that can harm water safety. It’s key to know about backflow scenarios to avoid water contamination risks.

Backflow risks often come from seemingly safe equipment and connections. The biggest dangers include:

- Hoses submerged in dirty mop buckets

- Improperly connected dishwashing equipment

- Spray nozzles touching contaminated surfaces

- Utility sink connections with compromised integrity

Indirect cross-connections are the most common backflow risks in kitchens. For example, a water hose in a utility closet might fall into a mop bucket with cleaning chemicals.

Kitchen staff must watch out for contamination points. Regular checks and keeping equipment in good shape can lower the risk of backflow incidents. These incidents can harm food and water safety.

Preventing backflow is not just a regulatory requirement—it’s a critical component of protecting public health in food service establishments.

By knowing these common scenarios, you can take steps to protect your kitchen’s water. This ensures food safety standards are met.

Emergency Procedures for Water Supply Interruption

Water supply interruptions can be a big challenge for food service places. Knowing how to prevent backflow is key during these times. Quick action can help keep food safe and avoid health risks.

When a water supply issue happens, you need a solid plan. Your emergency steps must be clear and documented. This protects your customers and your business.

Written Emergency Plan Requirements

A good emergency plan should have clear steps for water issues. It should cover:

- Quick checks on water quality and if it’s available

- Alternatives for storing and preparing food

- How to talk to local health authorities

- Training for staff on emergency actions

Steps for Regulatory Compliance

When water is cut off, you must act fast to keep food safe. Important steps include:

- Call the local health department within an hour of noticing the issue

- Stop making food if you can’t use safe water

- Use other ways to sanitize food

- Keep records of what you do during the emergency

Remember, being proactive can stop health risks and reduce disruptions.

Conclusion

Knowing which plumbing device prevents backflow is key in food service. It helps keep everyone safe. Backflow prevention devices are vital in kitchens.

Food safety needs strong protection of water systems. Knowing about cross-connections and backflow prevention is important. Tools like air gaps and double-check valve assemblies are essential.

Keeping your plumbing systems in check is a must. Regular checks and maintenance show you care about health standards. ServSafe rules highlight the importance of these steps.

Being proactive in backflow prevention is good for your business. Train your staff, stay up-to-date with rules, and see these steps as part of your food safety plan.